Maintenance Service

Maintenance strategy & planning is a crucial activity to manage equipment fleet. Today at the age of Industry X.0, maintenance strategy became more smart and technology driven basically focusing to the Predictive & self maintenance. The machines are becoming intelligent to do it’s self diagnostic which is the futuristic strategy for Industry. We at Equiptech provides all aspects of maintenance support from consulting to manpower engagement to meet the requirement of maintaining large fleets of industrial machineries mainly Heavy equipment.

Our Industry experts from the leading OEMs, is having rich experience in Heavy machinery. The regular maintenance under the expert supervision and correct strategy helps to predict when failure is likely to occur, allowing the customer to find a solution to problems before they happen. We provide expert advises to implement smart technologies to help the maintenance job for the Giant machinery at any moment at any location. We assist the machine owners to adopt suitable maintenance strategy as per the ground conditions.

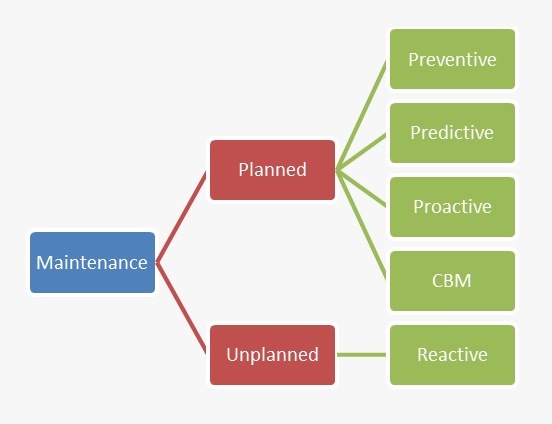

Breakdown maintenance to predictive or, autonomous maintenance describe the complete maintenance life cycle of machineries. We at Equiptech provides different type of maintenance throughout the life cycle of a machine.

- Reactive Maintenance – Our experts in wide range of equipment & technology takes care of trouble shooting, faulty analysis/rectification, breakdown analysis/rectification etc in machineries. Competency of our Reactive maintenance service is our knowledgeable technical experts experienced in different equipment since many decades. They are trained by OEMs for their model.

- Schedule/Preventive Maintenance – Proper scheduling of maintenance or, preventive maintenance involves regular systematic inspections, modification and replacement of components as well as performance testing and analysis. A successful preventive maintenance program extends equipment life and minimizes unscheduled downtime caused by equipment breakdown.

- Proactive Maintenance – This type of maintenance occur before breakdowns happen and designed to increase reliability and decrease downtime by the help of smart technology. This includes both Predictive and Condition based monitoring. The primary difference between them is the way in which maintenance is measured.

- Predictive Maintenance – Predictive maintenance relies on precise formulas in addition to sensor measurements (temperature, vibration, noise), and maintenance work is performed based on the analysis of these parameters. In this way, predictive maintenance is a very exact form of maintenance because it predicts future maintenance events.

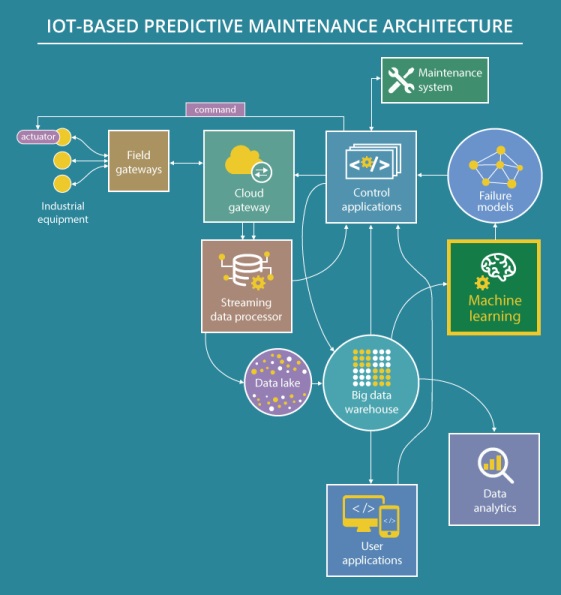

- CBM – On the other hand, condition-based maintenance relies only on real-time sensor measurements. Once a parameter reaches an unacceptable level, maintenance workers are dispatched. This means that condition-based maintenance systems perform work only in the moment it is needed. Our team combination with equipment experts/technicians and Instrumentation & IT professionals creates an unique digital platform to meet the goal of CBM based on IoT and sensor based real-time technology/telematics. We help the client to implement telematics from reputed technology provider and also we do the integration or, do the customisation by in house development to meet the objective of CBM.

This is an advisory services we provide to our client helping them to establish maintenance policy/philosophy to maintain their equipment fleets or, individual machinery. We help our client to implement maintenance strategy with proper documentation and enable them to produce large data for analysis. Following are the core areas under our maintenance advisory services :

- Create maintenance philosophy, strategy & policy

- Maintenance process consulting and documentation

- Work management workflow design

- Computerised Maintenance Management System (CMMS) evaluations

- Legacy system migration

We at Equiptech design different types of service contract to suit the client ground conditions. We do the in-depth study & inspection of equipment fleet and based on the economical & feasible solution, we recommend client to adopt suitable type of maintenance contract with their vendor. We also directly execute various type of service contracts with our own engineers and manpower at customer site. Following are the service contracts we deal with :

- MARC (Maintenance & Repair Contract) – MARC sometime become the best option for maximum productivity and cost savings. We can provide all maintenance and repair for a guaranteed cost per hour for a specified period of time.

- MARC can ensure that you achieve the longest possible life at the lowest possible User is relieved from equipment maintenance at a cost of mutually agreed payment against every working hour and available hour achieved from the equipment.

- Equipment upkeep including supply of spares and consumables (except HSD) is our responsibility.

- Tyre management and equipment operation is an optional scope which also can be added under this contract

- FMC/CMC (Full/Comprehensive Maintenance Contract) – User is relieved from equipment maintenance at a cost of mutually agreed payment against every working hour and available hour achieved from the equipment. Equipment upkeep including supply of spares is our responsibility. Oil and Lubricants (except HSD) may be supplied by us at additional cost per hour.

- AMC (Annual Maintenance Contract) – This is known to be most economical service contract in Industry. User is relieved from equipment maintenance at a cost of mutually agreed payment against every available hour achieved from the equipment.Equipment upkeep to be done under our technical supervision whereas procurement and supply of spares and oil & lubricants in right time is responsibility of the user.

- GPGSC (Guaranteed Performance against Guaranteed Spares Contract) – User maintains the equipment with a list of spares recommended by our technicians for a guaranteed level of performance. HSD and Oil & Lubricants are used by the user as per requirement and recommendation.A list of estimated spares required for annual operation is provided year wise and the user is required to maintain the stock at the beginning of the operational year.

-

CCC (Cost Cap Contract) – User maintains the equipment with spares recommended by our technical expert experienced in particular equipment for a guaranteed level of performance. HSD and Oil & Lubricants are used by the user as per requirement and recommendation. A value of estimated spares required for annual operation is guaranteed year wise and the user is required to pay the amount at the beginning of the operational year so as to keep the material available in user’s stock.

Overhauling of a machine is defined as a process of general maintenance performed on a machine or other industrial equipment.

The goal of overhauling is to keep the system in serviceable condition. Overhauling of complete equipment or, a assembly part is a highly technical job for which in depth technical knowledge and infrastructural facility is required.

We at Equiptech take overhauling or, repairing of complete equipment at customer workshop or, our associate’s workshop. We have associates with large infrastructural facility for FIP callibraton, engine overhauling, transmission overhauling etc.

We normally take the contract for heavy earthmoving equipment for the reputed brand like BEML, L&T Komatsu, TATA Hitachi etc.

Comes first to maintain Heavy machinery. Equiptech with Global technology partners provides various maintenance support equipment & technology. These equipment are used for safe maintenance of heavy machineries and also enhance the efficiency of maintenance staff to reduce the Mean time between failures. Some of the path breaking technology like Tire press, Dump body exchange system, advanced filtration system, Online oil sampling, remote control track elevating equipment, rim & hub handling system etc are being promoted by us along with our Principle M/s Equipment placement Australia.

The future of proactive maintenance shall be driven by basically new age technology like IoT, AI, Big data on cloud computing, Machine learning, 3D printing and Block chain. In future, machine-to-machine communication, sensor developments, big data and analytics will change the relationship between the factory and the maintenance engineer. Machine could be able to self-diagnose any part failures, order replacement components from a supplier, and install them with minimal human intervention.

A real-time vehicle health monitoring capability through a connected vehicle platform combined with an early warning prescriptive service maintenance approach to detect, diagnose and rectify such issues could have helped in situations like these and deliver delightful customer experiences.

More data will be available for maintenance engineers to analyse and a real-time simulation of the plant shall be on operation. Leveraging IoT Sensor Data, Decision Models, Analytics and Decision rules can help prescribe the required maintenance well ahead of time. Accordingly the parts can be produced at customer site itself by using 3D printing or, adhesive manufacturing technology which shall bring down the supply chain time towards replacement of parts after failure. In this ever-evolving smart world, prescriptive maintenance can become the new norm.

We at Equiptech has partnered with OEMs and technology provider to help the customer to solve complex maintenance problems by leveraging technology for future. From planning to evolution – we’ll guide you through every stage of IoT implementation strategy.

Operation of Heavy machinery is a challenging job which requires skill and extensive knowledge base. The productivity and safe operation of HEMM achieves high efficiency. We offer various type of training for the operator & technicians which include class room training, online training, field training and Simulator training.

Our e-Learning Technician Training involve various modules which are created for entry-level operators, technicians, equipment owners, and others looking for basic knowledge on heavy equipment safety, pre-operation maintenance, and basic operating procedures. We have also designed expert level of technician training module which include hand on experience on the equipment at field.

We have been associated with the technology provider for giving ultimate platform for Simulation to operate HEMM. This new age simulator brings a virtual reality for the operator to enhance their driving & operation skill before stepping to the mines.

We are building a centre of excellence for training of personnel in the field of HEMM, flying machines, material handling equipment etc.

Equipment Type

EARTHMOVER

CONSTRUCTION

BULK MATERIAL

DEFENCE

RAILWAY

CRUSHER

ELECTRONICS

UAV